In today’s technology-driven world, motors are everywhere — from electric vehicles 🚗 and industrial machines 🏭 to washing machines and drones. But have you ever wondered what enables these motors to start, stop, speed up, slow down, or even reverse direction smoothly?

The answer lies in Power Electronics — the bridge between electrical energy and mechanical motion. 💡

Power electronics has transformed how motors operate, making them more efficient, precise, and intelligent. In this article, we’ll explore how power electronics is applied in motor drives, its working principles, types of converters used, and its role in modern automation systems.

Let’s switch on the power! ⚙️⚡

🧠 What is Power Electronics?

Power Electronics is the study and application of electronic devices that control and convert electrical power efficiently from one form to another.

It deals with converting electrical energy (AC or DC) into a desired voltage and frequency suitable for driving motors and other loads.

🔋 Typical Power Conversions:

-

AC → DC (Rectification)

-

DC → AC (Inversion)

-

DC → DC (Chopper or Converter)

-

AC → AC (Cycloconverter or Matrix Converter)

In motor drives, these conversions help regulate speed, torque, and direction precisely.

🌀 What Are Motor Drives?

A motor drive is an electronic system that controls the operation of an electric motor by adjusting its input voltage and current.

It acts as the “brain” and “muscle” of the motor system — taking commands, processing them, and delivering power to achieve desired motion.

A typical motor drive system consists of:

-

Power Converter (for power control)

-

Controller (for decision making)

-

Motor (for mechanical output)

-

Feedback Sensors (for monitoring speed, position, etc.)

📈 Together, they enable functions like speed control, torque regulation, and braking.

⚙️ The Role of Power Electronics in Motor Drives

Power electronics provides flexibility and efficiency in controlling motors by allowing smooth variation of electrical parameters.

Here’s how it works step by step:

🔋 Step 1: Power Conversion

The incoming electrical power (AC from the grid or DC from a battery) is first converted to a suitable form.

For example:

-

In Electric Vehicles: DC battery power → 3-phase AC (via inverter)

-

In Industrial Machines: AC grid power → DC (rectifier) → variable AC (inverter)

🧩 Step 2: Control and Regulation

The converted power is then regulated to control:

-

Speed (by varying frequency or voltage)

-

Torque (by adjusting current)

-

Direction (by changing phase sequence)

🧠 Step 3: Feedback and Monitoring

Sensors continuously monitor parameters like motor speed, current, and temperature. The controller compares these with reference values and adjusts the power electronics accordingly — forming a closed-loop control system.

🔌 Power Electronic Devices Used in Motor Drives

Modern motor drives rely on semiconductor devices capable of switching power rapidly and efficiently.

Common devices include:

| Device | Full Name | Application |

|---|---|---|

| Diode | Rectifier Diode | AC to DC conversion |

| Thyristor (SCR) | Silicon Controlled Rectifier | High-power AC drives |

| MOSFET | Metal Oxide Semiconductor Field Effect Transistor | Low to medium power drives |

| IGBT | Insulated Gate Bipolar Transistor | High-efficiency motor control |

| GTO | Gate Turn-Off Thyristor | Large industrial drives |

💡 Among these, IGBTs are the most widely used in modern drives due to their high efficiency and fast switching.

⚙️ Types of Power Electronic Converters in Motor Drives

Different types of converters are used depending on the motor type and application:

1️⃣ Rectifiers (AC → DC)

Used in DC motor drives to provide a controlled DC supply.

-

Controlled Rectifier: Uses SCRs to regulate output voltage.

-

Example: Variable speed DC motor drives in steel rolling mills. 🏭

2️⃣ Choppers (DC → DC)

Used to vary the DC voltage supplied to DC motors.

-

Works by switching the supply on and off rapidly.

-

Example: Electric vehicles use choppers for speed control. 🚗

3️⃣ Inverters (DC → AC)

Converts DC into variable-frequency AC for AC motors.

-

Voltage Source Inverter (VSI) and Current Source Inverter (CSI) are common.

-

Example: Induction motor drives, EV traction systems. ⚡

4️⃣ Cycloconverters (AC → AC)

Directly converts AC at one frequency to AC at another frequency.

-

Used in large synchronous and induction motor drives for heavy-duty applications like cement mills or ship propulsion. ⚓

⚡ Motor Types Controlled by Power Electronics

Different motor types require different control strategies and power converters. Here’s a quick breakdown:

| Motor Type | Power Converter | Control Method | Application |

|---|---|---|---|

| DC Motor | Chopper/Rectifier | Voltage Control | Electric traction, cranes |

| Induction Motor | Inverter | V/f Control or Vector Control | Industrial automation |

| Synchronous Motor | Inverter | Vector Control | Robotics, precision motion |

| Brushless DC Motor (BLDC) | Inverter | Electronic Commutation | Drones, EVs, HVAC |

| Stepper Motor | Pulse Controller | Position Control | 3D printers, CNC machines |

🧩 Each combination provides specific advantages — from precise position control to energy-efficient high-speed rotation.

🧠 Control Strategies in Motor Drives

Power electronics enables advanced control algorithms for efficient performance. The two major control techniques are:

⚙️ 1. Scalar Control (V/f Control)

-

Maintains a constant ratio between voltage (V) and frequency (f).

-

Simple and reliable, used in low-cost drives.

-

Suitable for induction motors.

🧮 2. Vector Control (Field-Oriented Control)

-

Separates torque and flux control (like in DC motors).

-

Allows precise speed and torque regulation.

-

Used in high-performance drives such as electric vehicles or robotics. 🤖

🧰 Applications of Power Electronics in Motor Drives

Power electronics is the backbone of almost all modern motor-based systems. Here are a few practical applications:

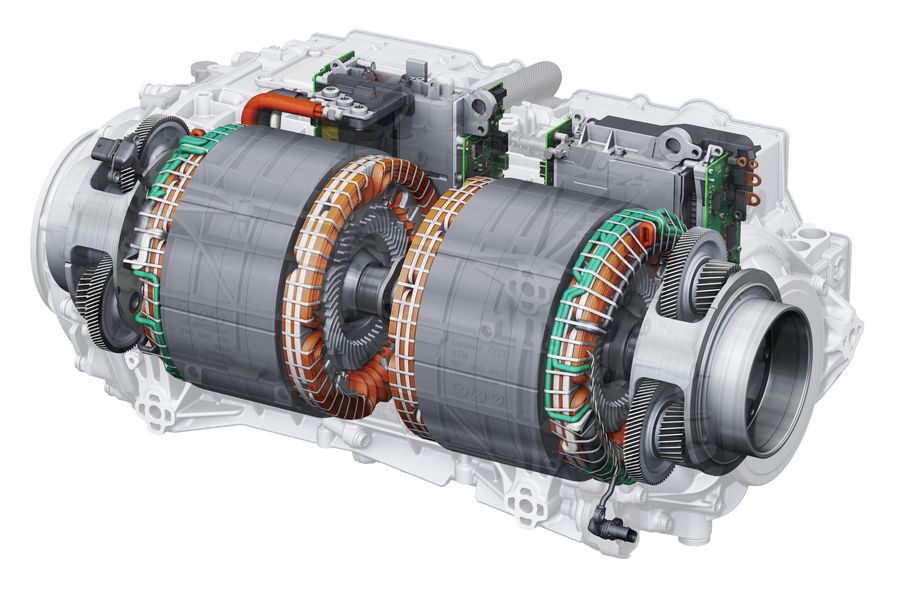

🚗 1. Electric and Hybrid Vehicles

-

Inverters convert battery DC to AC for propulsion motors.

-

Regenerative braking converts mechanical energy back into electrical energy. 🔋

🏭 2. Industrial Automation

-

Drives control conveyor belts, robotic arms, pumps, and fans.

-

Enhances production efficiency and reduces energy waste.

🏠 3. Household Appliances

-

Variable-speed washing machines, air conditioners, and refrigerators use inverters for energy-efficient operation. 🧺

✈️ 4. Aerospace and Defense

-

Aircraft actuators and UAV propulsion use power electronic motor drives for precision and reliability. ✈️

🌱 5. Renewable Energy Systems

-

Wind turbines and solar tracking systems use motor drives for optimal alignment and energy capture. 🌞💨

🔋 Advantages of Using Power Electronics in Motor Drives

✅ Precise Control: Accurate speed and torque regulation.

✅ High Efficiency: Minimal power loss through smart switching.

✅ Compact Design: Smaller systems with higher power density.

✅ Soft Start/Stop: Reduces mechanical stress on motors.

✅ Regenerative Capability: Converts kinetic energy back into electrical energy.

✅ Automation Ready: Easily integrates with PLCs and sensors for smart factories.

⚠️ Challenges and Considerations

Despite its advantages, power electronic drives face challenges:

-

Electromagnetic Interference (EMI): High switching speeds cause noise.

-

Thermal Management: Devices like IGBTs generate heat.

-

Complex Control Systems: Requires advanced algorithms.

-

High Initial Cost: More expensive than traditional drives.

However, ongoing research in wide-bandgap semiconductors (SiC, GaN) and digital signal controllers (DSPs) is overcoming many of these issues. 🚀

🔮 The Future of Power Electronics in Motor Drives

The next generation of motor drives will be smarter, smaller, and more efficient. Expect to see:

-

AI-assisted predictive control for fault detection 🧠

-

Wireless motor monitoring via IoT connectivity 🌐

-

Regenerative energy systems in almost all electric vehicles 🔋

-

SiC and GaN-based inverters offering ultra-fast switching and minimal losses ⚙️

The future of motion control is not just electric — it’s intelligent. 🤖⚡

📌 Conclusion: Power Electronics — The Pulse of Modern Motion

From high-speed trains and robotics to fans and EVs, power electronics is the unseen hero making motors smarter, faster, and greener. 🌍

By efficiently controlling voltage, frequency, and current, it enables precision and energy savings that were once impossible. The fusion of power electronics, control systems, and digital intelligence is redefining how the world moves. 🌐⚙️